3BHE024415R0101 使用FacilityView进行可视化

能够检查产品和员工在展位上花费的时间,使操作员能够监控(可视化)实际的运行状态。这使得能够注意到加班、员工使用不足以及工作过程中的不均衡,从而可能导致各种改进(成本降低)。

从各个远程位置进行监控/批次管理

云服务使得在不同位置的远程监控和批量管理成为可能。

管理员的灵活设置和操作变更

管理员可以使用标准工具来配置设置并更改操作,以改变工厂生产线布局。

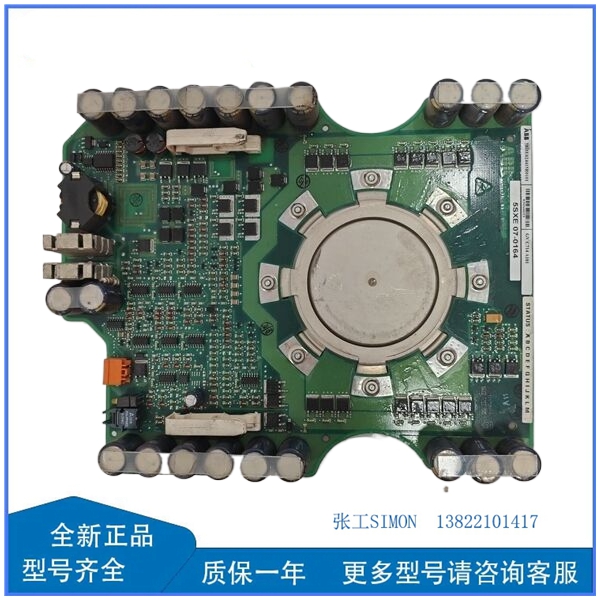

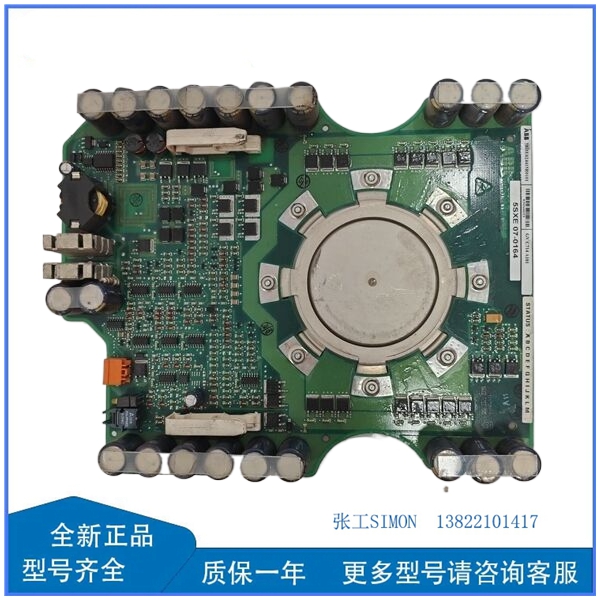

联系人:张工 Simon

联系电话:+8613822101417

电子邮箱:sales@qimingplc.com

服务热线

服务热线

13822101417

型号:3BHE024415R0101

中文产品介绍:

系统概述

3BHE024415R0101技能差异和工人工作量状态使得确定电池生产精加工过程中的实际操作状态变得困难。了解工人在电池生产中的当前状态以及待加工产品的停留时间,可以可视化实际操作状态,从而为提高生产效率打开大门。

除了了解运营的实际状况外,此可视化还可以作为评估工作效率改进措施有效性的工具。

成品的进出台账时间通过光电管自动测量,工人参与时间通过脚踏开关自动测量。数据通过CONPROSYS nano(一种用于数字化穿插的本地设备的必备远程I/O设备)收集,然后传输到CONPROSYS TM恒定监控和遥测系统。然后,产品和工人在展示柜内停留的时间在时间轴上记录,然后数据被发送到 FacilityView®,这是一个通过4G LTE进行远程监控的云服务。这些数据通过预包装工具在仪表板的图表中显示,这些工具使在没有任何编码的情况下创建屏幕变得非常简单。

优势/结果

3BHE024415R0101使用FacilityView进行可视化

能够检查产品和员工在展位上花费的时间,使操作员能够监控(可视化)实际的运行状态。这使得能够注意到加班、员工使用不足以及工作过程中的不均衡,从而可能导致各种改进(成本降低)。

从各个远程位置进行监控/批次管理

云服务使得在不同位置的远程监控和批量管理成为可能。

管理员的灵活设置和操作变更

管理员可以使用标准工具来配置设置并更改操作,以改变工厂生产线布局。

英文产品介绍:

System Overview

The skill differences and workload status of workers in 3BHE02445R0101 make it difficult to determine the actual operational status during the battery production precision machining process. Understanding the current status of workers in battery production and the dwell time of products to be processed can visualize the actual operational status, thus opening the door to improving production efficiency.

In addition to understanding the actual operational situation, this visualization can also serve as a tool for evaluating the effectiveness of measures to improve work efficiency.

The entry and exit time of finished products is automatically measured by photoelectric tubes, and the worker participation time is automatically measured by foot switches. The data is collected through CONPROSYS nano, a necessary remote I/O device for digital interleaving of local devices, and then transmitted to the CONPROSYS TM constant monitoring and telemetry system. Then, the time spent by the product and workers inside the display cabinet is recorded on the timeline, and the data is sent to FacilityView ®, This is a cloud service that enables remote monitoring through 4G LTE. These data are displayed in dashboard charts through pre packaged tools, which make it very easy to create screens without any coding.

Advantages/Results

3BHE02445R0101 Visualization using FacilityView

Being able to check the time spent by products and employees at the booth, allowing operators to monitor (visualize) the actual operational status. This enables attention to overtime, underutilization of employees, and imbalances in the work process, which may lead to various improvements (cost reductions).

Monitor/batch management from various remote locations

Cloud services enable remote monitoring and batch management in different locations.

Flexible settings and operational changes for administrators

Administrators can use standard tools to configure settings and modify operations to change the layout of factory production lines.

在线留言

ONLINE MESSAGE