500CMP04 HE401314-0001 1MRB150051R1 自动化工作时间管理以改进工作

通过自动化收集工作时间数据,可以减少在管理上花费的人工小时,而不是像过去一样手动记录工人自我报告的数据。这些客观记录的数据可以用来进行工作改进。

联系人:张工 Simon

联系电话:+8613822101417

电子邮箱:sales@qimingplc.com

服务热线

服务热线

13822101417

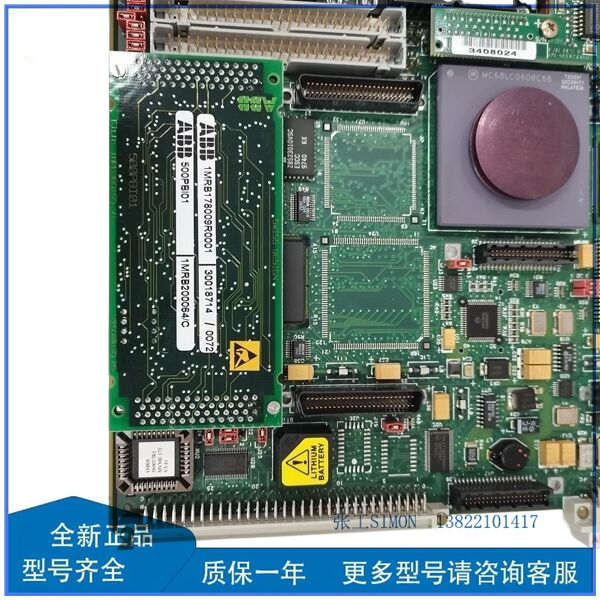

型号:500CMP04 HE401314-0001 1MRB150051R1

中文产品介绍:

500CMP04 HE401314-0001 1MRB150051R1使用物联网技术进行操作员出勤管理

我们设计了一套管理系统来管理细胞生产操作员的出勤情况。通过在细胞生产区域安装运动传感器和物联网设备来收集有关操作员移动的信息。使用CONPROSYS™ telemeter系统(CPS-TM341系列)和CONPROSYS™ nano(远程I/O),可以对20个混合区域进行集中监控,收集的数据可以使用Web浏览器在任何地方查看。收集的数据还可以使用Excel等电子表格软件下载并整理,以分析操作员出勤和不到勤的时间、频率和时间段等。

500CMP04 HE401314-0001 1MRB150051R1 细胞生产系统挑战

工作工时的记录是手动进行的,导致了大量的管理工时。此外,由于工作工时的记录是基于工人自我报告的数据,如果这些数据要用于分析,工人必须保持客观。

尽管我们的目标是识别损失时间和浪费流程,以实现提高生产力,但由于无法正确测量工作时间,使得分析成为不可能。

无法准确计算工作人工成本。

通过CONPROSYS解决问题

物联网和数字化的优势

500CMP04 HE401314-0001 1MRB150051R1 自动化工作时间管理以改进工作

通过自动化收集工作时间数据,可以减少在管理上花费的人工小时,而不是像过去一样手动记录工人自我报告的数据。这些客观记录的数据可以用来进行工作改进。

生产效率的提高

现在可以准确记录工作时间,而不是像以前那样难以确定。这意味着也可以准确记录员工的缺勤时间,例如在工作过程中员工离开工作岗位补充零件或消耗品的时间,从而能够准确计算人工成本,并优化工厂的生产线和零件布局。 此外,操作员出勤状态的可视化也有望提高操作员的意识。

英文产品介绍:

500CMP04 HE401314-0001 1MRB150051R1 uses IoT technology for operator attendance management

We have designed a management system to manage the attendance of cell production operators. Collect information about operator movements by installing motion sensors and IoT devices in the cell production area. Using CONPROSYS ™ Telemeter system (CPS-TM341 series) and CONPROSYS ™ Nano (remote I/O) can centrally monitor 20 mixed areas, and the collected data can be viewed anywhere using a web browser. The collected data can also be downloaded and organized using spreadsheet software such as Excel to analyze operator attendance and absenteeism time, frequency, and time periods.

500CMP04 HE401314-0001 1MRB150051R1 Cell Production System Challenge

The recording of working hours is done manually, resulting in a significant amount of management time. In addition, since the recording of working hours is based on self-reported data from workers, if these data are to be used for analysis, workers must maintain objectivity.

Although our goal is to identify lost time and wasted processes to improve productivity, the inability to accurately measure work time makes analysis impossible.

Unable to accurately calculate labor costs.

Resolve issues through CONPROSYS

The advantages of the Internet of Things and digitization

500CMP04 HE401314-0001 1MRB150051R1 Automated Work Time Management to Improve Work

By automating the collection of work time data, it is possible to reduce the number of manual hours spent on management, rather than manually recording workers' self-reported data as in the past. These objectively recorded data can be used for work improvement.

Improvement of production efficiency

Now it is possible to accurately record working hours, rather than being difficult to determine as before. This means that employee absenteeism time can also be accurately recorded, such as the time when employees leave their work positions to replenish parts or consumables during the work process, thereby accurately calculating labor costs and optimizing the factory's production line and parts layout. In addition, visualizing the attendance status of operators is also expected to enhance their awareness.

在线留言

ONLINE MESSAGE