Elmo G-TUB30-480ERSS0 显示整体资产状况,按位置显示概要级数据

通过数据分析可视化监控资产,包括:

速度和加速度,各自的频段

温度

整体轴承严重程度

联系人:张工 Simon

联系电话:+8613822101417

电子邮箱:sales@qimingplc.com

服务热线

服务热线

13822101417

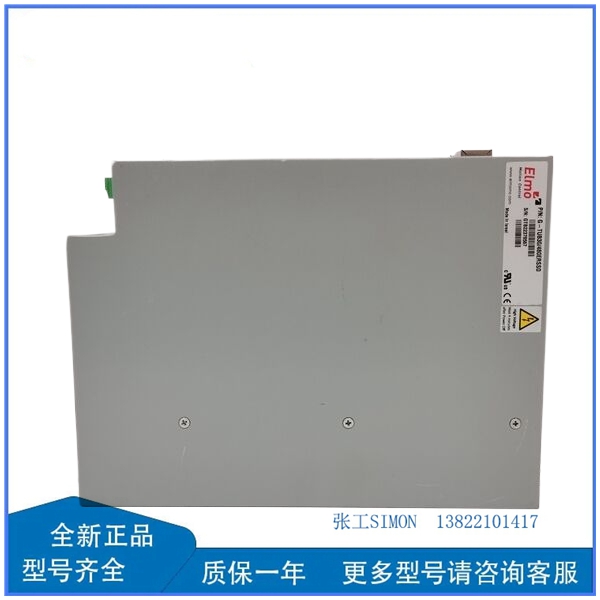

型号:Elmo G-TUB30-480ERSS0

中文产品介绍:

Elmo G-TUB30-480ERSS0用于对重要、二级机器进行振动监测。分析振动传感器收集高分辨率数据的突发,并且可以检测最常见的机器故障。

振动屏幕传感器最适合用于标准机器(而非对生产至关重要的机器)的无线振动监测,以检测基本的机器健康状况,例如资产表现是良好还是不佳。

除了无线振动监测,还有有线振动传感器,例如Prüftechnik 的 VibGuard。这些有线振动传感器可以收集持续、高分辨率的振动测量数据,以支持非常详细的数据分析。它们在复杂和生产关键机器的振动监测中表现良好,然而,这些先进的传感器需要高级培训。

Elmo G-TUB30-480ERSS0 显示整体资产状况,按位置显示概要级数据

通过数据分析可视化监控资产,包括:

速度和加速度,各自的频段

温度

整体轴承严重程度

Elmo G-TUB30-480ERSS0提供广泛的远程状态监测服务和支持,以改进您的维护计划。从培训到购买后的设置,我们的远程状态监测 专家可以利用我们的振动解决方案帮助您减少意外停机时间并防止可能灾难性的故障。

开发预测性维护振动监测计划不一定要复杂、耗时或昂贵。您可以从小规模的试点项目开始。

英文产品介绍:

Elmo G-TUB30-480ERSS0 is used for vibration monitoring of important and secondary machines. Analyze the sudden collection of high-resolution data by vibration sensors and detect the most common machine faults.

Vibration screen sensors are best suited for wireless vibration monitoring of standard machines (rather than production critical machines) to detect basic machine health conditions, such as whether asset performance is good or poor.

In addition to wireless vibration monitoring, there are also wired vibration sensors, such as Pr ü ftechnik's VibGuard. These wired vibration sensors can collect continuous, high-resolution vibration measurement data to support very detailed data analysis. They perform well in vibration monitoring of complex and production critical machines, however, these advanced sensors require advanced training.

Elmo G-TUB30-480ERSS0 displays overall asset status and summary level data by location

Visualize monitoring assets through data analysis, including:

Speed and acceleration, respective frequency bands

Temperature

Severity of overall bearing

Elmo G-TUB30-480ERSS0 provides extensive remote condition monitoring services and support to improve your maintenance plan. From training to post purchase setup, our remote condition monitoring experts can use our vibration solution to help you reduce unexpected downtime and prevent potentially catastrophic failures.

Developing a predictive maintenance vibration monitoring plan does not necessarily have to be complex, time-consuming, or expensive. You can start with small-scale pilot projects.

3500/92 136180-01

3500/05-01-02-00-00-01

3500/40M(140734-01)

3500/40M 176449-01

3500/92 136180-01

3500/33 149986-01

3500/92 136188-02

3500/15 106M1079-0

3500/15-05-05-00

3500/33-01-00

3500/25-01-01-00

3500/92-02-01-00

3500/72M

3500/42M 140734-02

在线留言

ONLINE MESSAGE